Why Cutting a Basement Foundation for an Egress Window Matters

Cut egress window basement projects are a critical home improvement, changing a dark space into a safe, code-compliant living area. If you’re considering this project, here’s a quick overview:

Quick Answer: Cutting a Basement Window Opening

- Obtain permits from your local building department.

- Mark the opening to code (min 5.7 sq ft, 20″ W x 24″ H).

- Cut the concrete with a professional wall-mounted saw.

- Install a structural header if required.

- Frame and install the window with proper waterproofing.

- Excavate and install a window well (min 36″ projection).

- Add drainage to prevent water issues.

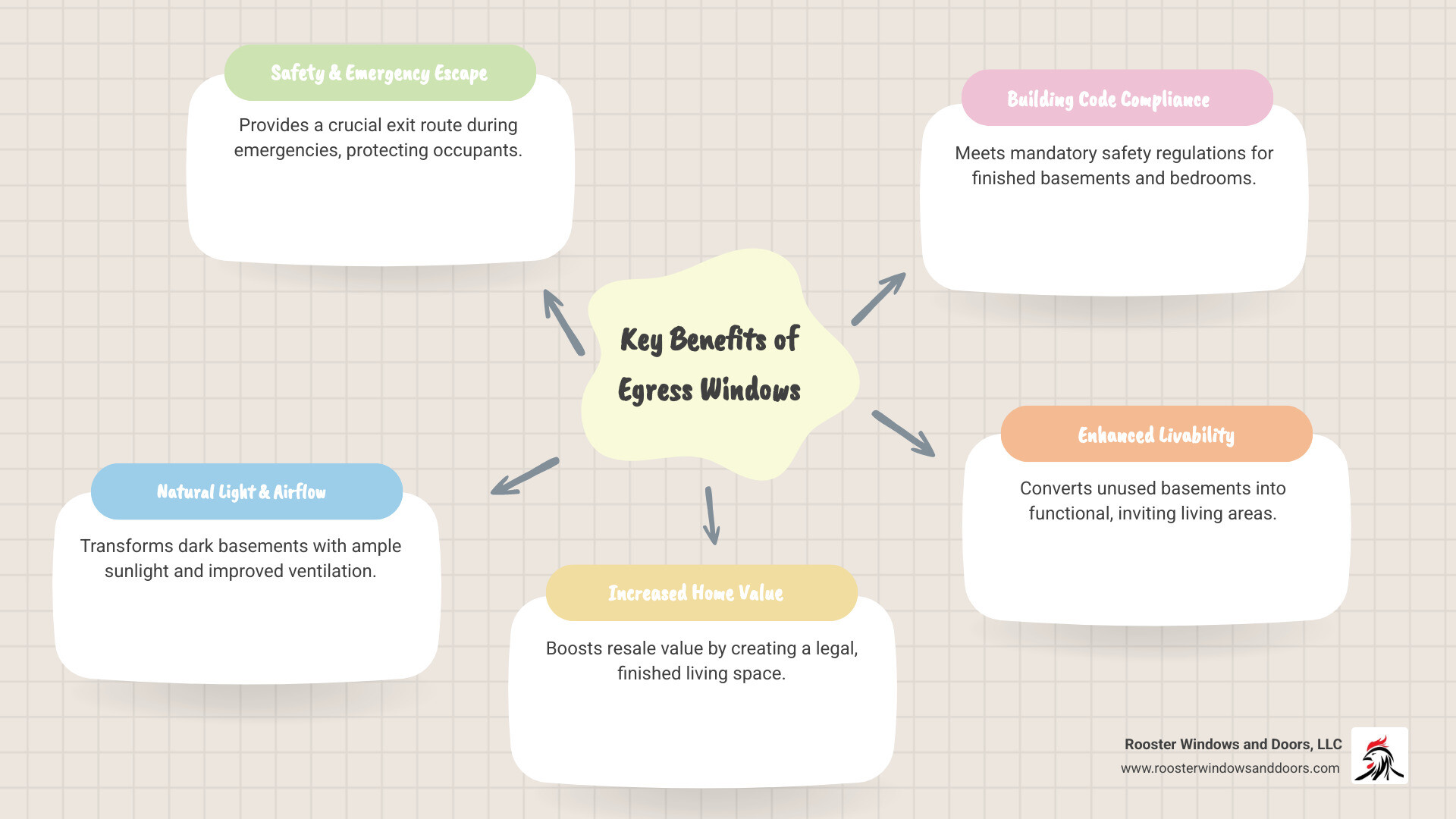

An egress window is a required emergency exit for any finished basement or below-grade bedroom. Beyond this life-saving function, it floods the space with natural light, improves ventilation, and increases your home’s resale value.

However, cutting through a concrete foundation is not a DIY job. It demands specialized equipment, structural knowledge, and precision. A mistake can compromise your home’s integrity, lead to water intrusion, and result in failed inspections. The process involves excavation, cutting through 8-10 inches of concrete, framing, waterproofing, and installing a drainage system—all of which must meet strict building codes.

I’m Piotr Wilk, and for over two decades, I’ve installed windows and doors throughout Chicagoland. I’ve seen what separates a safe, lasting cut egress window basement installation from a costly mistake. This guide will walk you through the essentials.

Understanding Egress Window Requirements Before You Cut

Before you cut egress window basement foundations, you must understand the rules. These aren’t suggestions; they are laws designed to save lives. While local codes in Chicagoland may vary slightly, they are all based on the International Residential Code (IRC).

Egress Window Building Codes and Permits

The IRC sets clear, non-negotiable standards for safety:

- Minimum Opening Area: 5.7 square feet, large enough for an adult to escape.

- Minimum Dimensions: At least 20 inches of clear width and 24 inches of clear height.

- Maximum Sill Height: No more than 44 inches from the finished floor, ensuring you can climb out without assistance.

- Operation: The window must be operable from the inside without keys, tools, or special knowledge.

Before starting, you must obtain a permit from your local municipality. This is not optional. Any structural change to your foundation requires a permit to ensure the work is inspected and verified for safety. Our team at Rooster Windows and Doors regularly manages the permit process throughout Chicagoland and knows what local departments expect. For more details, see our Basement Windows Complete Guide.

The Role of Window Wells

If your egress window is below ground level, a window well is essential. It provides the space to escape, channels light and air into your basement, and manages water.

IRC requirements for window wells include:

- Minimum Clear Area: 9 square feet.

- Minimum Projection: At least 36 inches from the foundation wall.

- Ladder: A permanently affixed ladder is required if the well is deeper than 44 inches.

Proper drainage is critical to prevent your window well from flooding. We connect the well’s drainage to your home’s drain tile or install a gravel pit. A sturdy window well cover is also a smart investment to prevent falls and keep out debris, but it must be easily removable from the inside.

Choosing the Right Window Style

Not all window styles are suitable for egress. Your choice must meet code while fitting your home’s needs.

- Casement windows are the gold standard. They crank open outward, providing a large, unobstructed opening that easily meets code.

- Sliding windows are another solid choice. One sash slides past the other to create the necessary clear opening.

- Single-hung windows can work if they are large enough to provide the required vertical clear space.

For frame materials, we recommend composite or fiberglass for their superior moisture resistance, which is crucial in a basement environment. Vinyl is another durable option. All our windows are designed for energy efficiency, helping to keep your basement comfortable and your energy bills down. Explore our options on our Basement Window page.

The Cost to Cut Egress Window Basement Walls and Complete the Job

When you plan to cut egress window basement openings, you’re making a significant investment. Let’s break down the costs so you know what to expect.

Egress Window Installation Cost Breakdown

A complete egress window installation in the Chicagoland area typically runs between $2,712 and $5,824, with most projects falling in the $2,600 to $3,500 range. This price reflects a complex, multi-step process:

- Concrete Cutting: $800 – $1,500. This requires industrial-grade saws and skilled operators to cut through 8-10 inches of foundation without compromising structural integrity.

- Excavation: $500 – $1,000. This covers digging the window well area and hauling away soil.

- Egress Window Unit: $600 – $1,800+. Prices vary based on size, style, and material (e.g., vinyl vs. fiberglass).

- Window Well & Drainage: $300 – $800+. This includes the well structure, gravel, and drainage connections.

- Labor, Permits & Structural Work: This covers skilled labor for framing, waterproofing, installing headers, and permit fees ($100 – $300).

For a more detailed estimate, see our Egress Window Installation Cost guide.

Factors That Influence the Final Price

Your specific situation will impact the final cost. Key variables include:

- Foundation Type: Poured concrete is often more expensive to cut than concrete block, but block may require more reinforcement.

- Window Size and Style: A larger, premium window will cost more than a basic, code-minimum unit.

- Structural Headers: If the wall is load-bearing, a steel header is required to support the weight above, adding $500 – $1,200 to the cost.

- Site Accessibility: Difficult access for equipment and workers can increase labor costs.

- Soil Conditions: Heavy clay or rocky soil in the Chicagoland area can make excavation more difficult and time-consuming.

| Foundation Type | Basic Installation | Complex Installation |

|---|---|---|

| Poured Concrete | $2,700 – $3,500 (standard size, easy access, minimal structural work) | $4,500 – $5,800 (larger window, difficult access, full structural header) |

| Concrete Block | $2,500 – $3,200 (standard size, easy access, basic reinforcement) | $4,200 – $5,500 (larger window, difficult access, extensive reinforcement) |

Budgeting for Egress Window Solutions

Think beyond the basic installation to get the best long-term value:

- Custom Window Wells: Upgrading from galvanized steel to a composite or stone well ($300 – $800 extra) can significantly improve curb appeal.

- Window Well Covers: A cover ($100 – $400) is a wise investment for safety, preventing falls and keeping out debris.

- Window Materials: A premium fiberglass window may cost more upfront than vinyl but offers better longevity and energy efficiency.

- Energy Efficiency: Features like Low-E glass and argon gas fills ($150 – $400 extra) can lower your heating and cooling costs, paying for themselves over time.

For more on available styles, explore our Egress Window Options guide.

How to Cut Egress Window Basement Foundations: A Step-by-Step Guide

The most critical phase of adding an egress window is cutting the foundation. There’s no room for error when you cut egress window basement walls. Here’s how professionals handle this complex task.

Step 1: Preparation and Site Layout

Meticulous preparation ensures a safe, code-compliant project.

First, we Call Before You Dig by dialing 811 to have all underground utility lines located and marked. This non-negotiable step prevents dangerous and costly accidents.

Inside, we seal off the work area with heavy-duty plastic to contain the immense amount of concrete dust. Outside, we create a precise excavation plan for the window well, considering soil conditions and access.

We then carefully measure and mark the rough opening from inside, ensuring the sill height is no more than 44 inches from the floor. We drill pilot holes to transfer these markings to the exterior, where we outline the final cut lines. This blueprint ensures perfect alignment.

Step 2: The Concrete Cutting Process

This step demands specialized tools and an expert hand to ensure a clean, accurate opening without causing structural damage.

We use a wall-mounted concrete saw that glides along a track for perfectly straight and level cuts. For the corners, we use a specialized ring saw to achieve true 90-degree angles, avoiding overcuts that can compromise waterproofing and structural integrity. All our saws use industrial-strength diamond blades and a wet cutting technique, where water suppresses dust and cools the blade for a cleaner, more efficient cut.

Our technicians wear full personal protective equipment (PPE), and all equipment is plugged into GFCI outlets for safety. The process differs slightly for poured concrete vs. concrete block, with block foundations requiring us to fill exposed cores with concrete to maintain stability.

Learn more about the installation process in our How to Install New Basement Window guide.

Step 3: Framing, Installation, and Waterproofing

With the opening cut, we build it out to be a secure, watertight, and energy-efficient part of your home.

If the wall is load-bearing, installing a structural header is essential to redistribute the weight from above. We then build a buck frame from pressure-treated lumber inside the opening, creating a rot-resistant surface to mount the window.

Using shims, we carefully level and plumb the window within the frame before securing it. A window that isn’t perfectly square won’t operate correctly.

Waterproofing is paramount. We apply flexible flashing tape in overlapping layers to shed water away from the opening. We use high-quality sealants around the exterior but never caulk the window’s weep holes, which are designed to let moisture escape. Finally, we ensure the window well drainage is properly connected to your home’s drainage system or a dedicated gravel pit to prevent water accumulation.

DIY vs. Professional Concrete Cutting: Risks and Rewards

There’s satisfaction in DIY projects, but when it comes to a cut egress window basement job, the stakes are incredibly high. You’re altering the very foundation of your home. While the DIY spirit is admirable, this is one project best left to professionals.

The Challenges of a DIY Cut Egress Window Basement Project

Attempting to cut a basement foundation yourself is one of the riskiest home improvement projects. The challenges are significant:

- Structural Risks: An improper cut or lack of support can lead to foundation cracks, settling, or even failure. The repair costs can be astronomical.

- Required Expertise: The job requires knowledge of excavation, concrete cutting, structural engineering, and advanced waterproofing—skills that take years to develop.

- Specialized Tool Costs: Professional concrete saws and diamond blades cost thousands to buy and are expensive to rent. The cost of tools alone can approach that of a professional installation.

- Personal Injury Danger: Industrial concrete saws are powerful and dangerous. The risk of severe injury from kickback, falling concrete, or dust inhalation is very real.

- Code Compliance Failures: Egress codes are strict. A failed inspection means costly rework and delays.

- Water Intrusion: Improper sealing and drainage are common DIY mistakes that lead to slow leaks, mold growth, and foundation damage.

Why Hiring a Professional is the Smartest Choice

At Rooster Windows and Doors, we’ve spent over two decades perfecting egress window installations in Chicagoland. Here’s why hiring a pro is the right call:

- Guaranteed Code Compliance: We know the local codes in communities like Naperville and Libertyville, ensuring your project passes inspection the first time.

- Structural Expertise: We know when and how to install structural headers to protect your home’s integrity, consulting with engineers when necessary.

- Proper Tools and Experience: We use professional-grade wall saws and ring saws for precise, clean cuts that a DIYer can’t replicate.

- Waterproofing Mastery: Our comprehensive approach to flashing, sealing, and drainage prevents leaks and protects your basement from moisture damage.

- Liability and Insurance: Our insurance protects you from financial risk if anything unexpected happens during the project.

- A Flawless Finish: We deliver a meticulous installation that looks great and performs perfectly for years to come.

Our Egress Window Installers Best Guide explains what to expect from a professional job.

Frequently Asked Questions about Cutting Basement Window Openings

Homeowners considering a cut egress window basement project often have the same questions. Here are answers to the most common concerns.

Can I cut a window opening in any basement wall?

Usually, yes, but a professional assessment is crucial. We must first evaluate several factors:

- Load-Bearing Walls: If a wall supports the house above, we must install a structural header to carry the load safely around the new opening.

- Obstructions: We check for hidden plumbing, electrical wiring, or HVAC ducts that may need to be rerouted before cutting.

- Foundation Condition: We assess the health of your poured concrete or block foundation, looking for any existing issues that could complicate the project.

Based on this assessment, we determine the safest and most effective location for your new window.

How long does it take to cut a concrete wall for a window?

The actual concrete cutting is surprisingly fast—often just a couple of hours with our professional equipment. However, the complete installation is a multi-day process.

A typical project timeline is about one week and includes:

- Preparation & Excavation: (1-2 days) Marking utilities, setting up dust containment, and digging the window well.

- Cutting & Opening Prep: (1 day) Cutting the concrete, removing the section, and preparing the opening.

- Framing & Window Installation: (1 day) Building the buck frame, setting the window, and applying initial waterproofing.

- Well Installation & Drainage: (1-2 days) Installing the well and connecting the drainage system.

- Finishing Work: (1 day) Completing interior/exterior trim, final sealing, and cleanup.

We take the time to do the job perfectly rather than rushing and compromising quality.

What are the biggest risks of improper concrete cutting?

The consequences of a poorly executed cut egress window basement project are severe and costly. The biggest risks include:

- Foundation Cracks & Structural Failure: Inaccurate cuts or a lack of proper support can create stress points that compromise your home’s entire structure.

- Water Leaks and Mold: Improper waterproofing is the leading cause of failure, leading to persistent leaks and hazardous mold growth that can affect your family’s health.

- Failed Inspections: If the project doesn’t meet local building codes, you will fail inspection, leading to forced work stoppages, costly rework, and significant delays.

- Costly Repairs: Fixing a botched job—from structural reinforcement to mold remediation—often costs far more than the initial professional installation would have.

These risks are why we are so committed to doing this work correctly. For a professional installation you can trust, contact us today!

Conclusion

When you cut egress window basement openings the right way, you transform an underused space into a safe, bright, and valuable living area. However, this is not a simple project.

Creating an egress window opening involves navigating complex building codes, executing precise concrete cuts, and applying expert waterproofing techniques to protect your home’s structural integrity. The stakes are high—an improper installation can lead to foundation cracks, water damage, and costly repairs.

At Rooster Windows and Doors, we have spent over two decades mastering these challenges throughout Chicagoland. Our team has the specialized equipment, structural knowledge, and proven techniques this demanding work requires. We handle every detail, from permits to final inspection, ensuring a flawless result.

Your family’s safety and your home’s integrity are too important to leave to chance. Let our experienced professionals provide a high-quality, flawless, and energy-efficient installation that gives you peace of mind.

For expert guidance and a professional egress window installation, contact us today!